Plastic Exhaust Mockup Kit

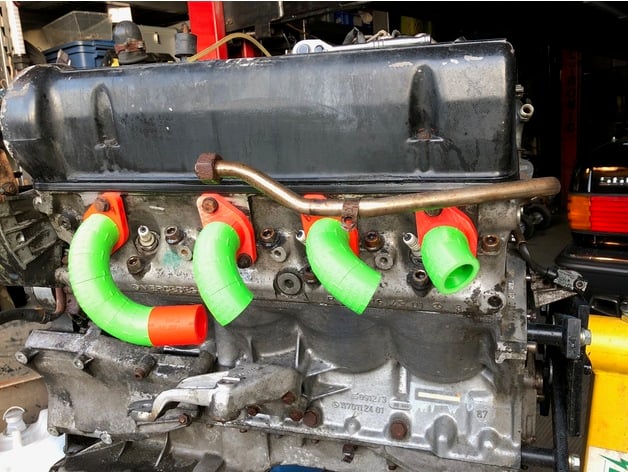

Exhaust header mockup using icengineworks modeling blocks.

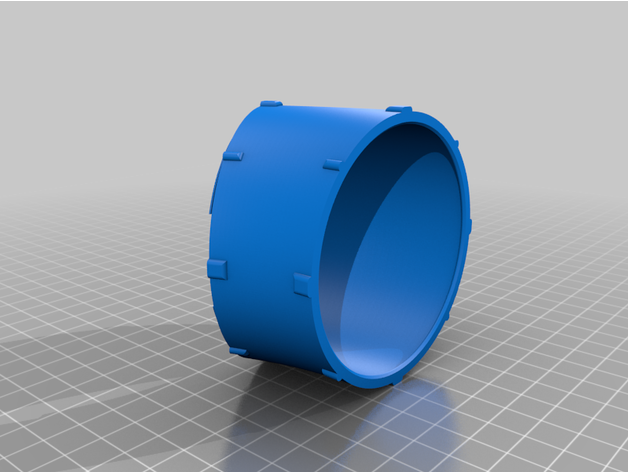

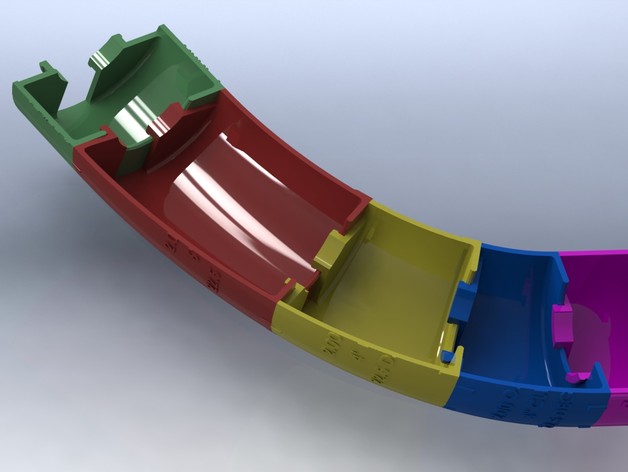

Plastic exhaust mockup kit.These 3d modeling kits allow you to revise rearrange and correct potential header configurations until you ve achieved the perfect design no wasted time or metal.Simply use icengineworks abs plastic modeling sections to mock up your headers and then build your actual custom headers to match.Components are sized to fit 1 1 2 schedule 40 pvc which is same od 1 3 4 as finished primary tubes used.

P ayr 2044 p ayr products replica long block engines mock up engine lightweight plastic short block removable cylinder heads chevy small block each part number.Custom pvc mock up kits kit comes with 1 or 2 collectors and 4 or 6 stub risers depending on engine size and style.The original ford gt40 had a pretty sweet exhaust system appropriately called a basket of snakes reflecting the intertwined tubes running over the engine and out the back.

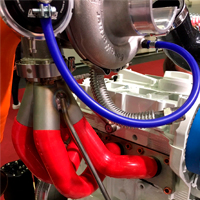

Custom pvc mock up kits custom exhaust systems custom pvc mock up kits up to 16 hp increase in some applications from a standard muffler system.The only requirements are that the engine is fitted in place with flanges and starter tubes and that exhaust collectors or collector dummies are firmly secured in.Icengineworks parts and accessories free shipping on.

Icengineworks exhaust header modeling blocks make custom.Header modeling kit build pipe dream hot rod magazine the kit is composed of rubber connectors that fit into a header flange to give a starting point for your primary pipe build.Because of the high cost and specialized nature of mandrel bending machines fabricators are forced to work with a selection of pre bent j bends and u bends to cut and splice tubes to make complicated configurations.

Pvc mock up kits aircraft exhaust corp bret shares his experience building a custom exhaust system.Aircraft exhaust pvc mockup kits from aircraft exhaust.Some of us look at a system like that and our first thought is of the time and frustration involved putting it together for the first time.

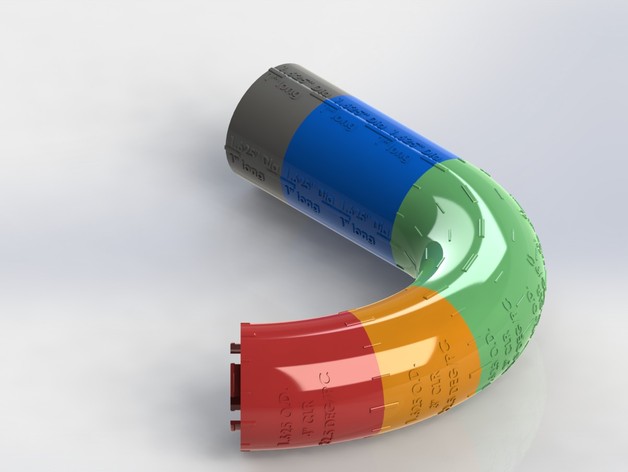

Interlocking plastic tubing sections of varying angles are marked to.Icengineworks precision exhaust header modeling systems the most important step in our system stage i allows builders using our patented plastic blocks to quickly generate the tubular shapes and geometry required to test fitment ease of fabrication and even set budgets for any project.Custom exhaust header design fabrication tools automotive exhaust systems headers and turbo manifolds can be time consuming and tedious projects.

Finally custom header fabrication is easy to do with the help of your 3d printer.No more spending over 4 figures for a plastic snap kit you might use once or twice.Find tools here to simplify and speed up fabrication of these jobs.

Tube bends snap together for ease of customization when laying out a new header or exhaust design for your next motorized project.These kits allow you to design and build your own system when there is not any other available to fit your airframe engine combo or just to get the most hp possible out of your engine.Tubes have bend radius printed on sides for ease of identification i also printed the different.

Two kit sizes are available to cover 4 or 8 cylinder applications.Replica mock up components free shipping on orders over.